The Storz & Bickel Venty is widely regarded as one of the best dry herb vaporizers available today. Manufactured in Germany by a company with a legacy dating back to 1998, the Venty stands out for its exceptional design and performance. In this post, we delve into the inner workings of the Venty, uncovering its engineering secrets through a detailed teardown.

Introduction to the Venty Vaporizer

The Venty vaporizer is a hybrid device that combines approximately 75% convection and 25% conduction heating. This unique blend provides superior vapor quality and flavor. Priced at $450 (minus 10% when you use the coupon code TVG10 at vape-smart), the Venty promises a premium vaping experience. Our teardown aims to understand the intricate design and engineering that make this device so exceptional.

This is the first post in my teardown series, where I explore the heating elements and vapor paths of the best dry herb vaporizers. Here is my Solo 3 teardown, and I'm working on the TM2 right now.

Mouthpiece and Cooling Mechanism

Starting with the most accessible component, the mouthpiece, we find a well-designed cooling mechanism. The mouthpiece features a screen and channels that cool the vapor before inhalation. It also includes an airflow control, allowing users to adjust the air intake according to their preference.

Body and Housing

The Venty's body is constructed from PEEK (Polyether Ether Ketone), a high-performance engineering plastic known for its mechanical strength and chemical resistance. After removing the “boost mode” instructions sticker and a blue O-ring, it becomes evident that the housing lacks visible screws.

Four orange dots serve as one-way covers, concealing hex screws underneath. Once these screws are drilled out, the housing can be removed, revealing the internal components.

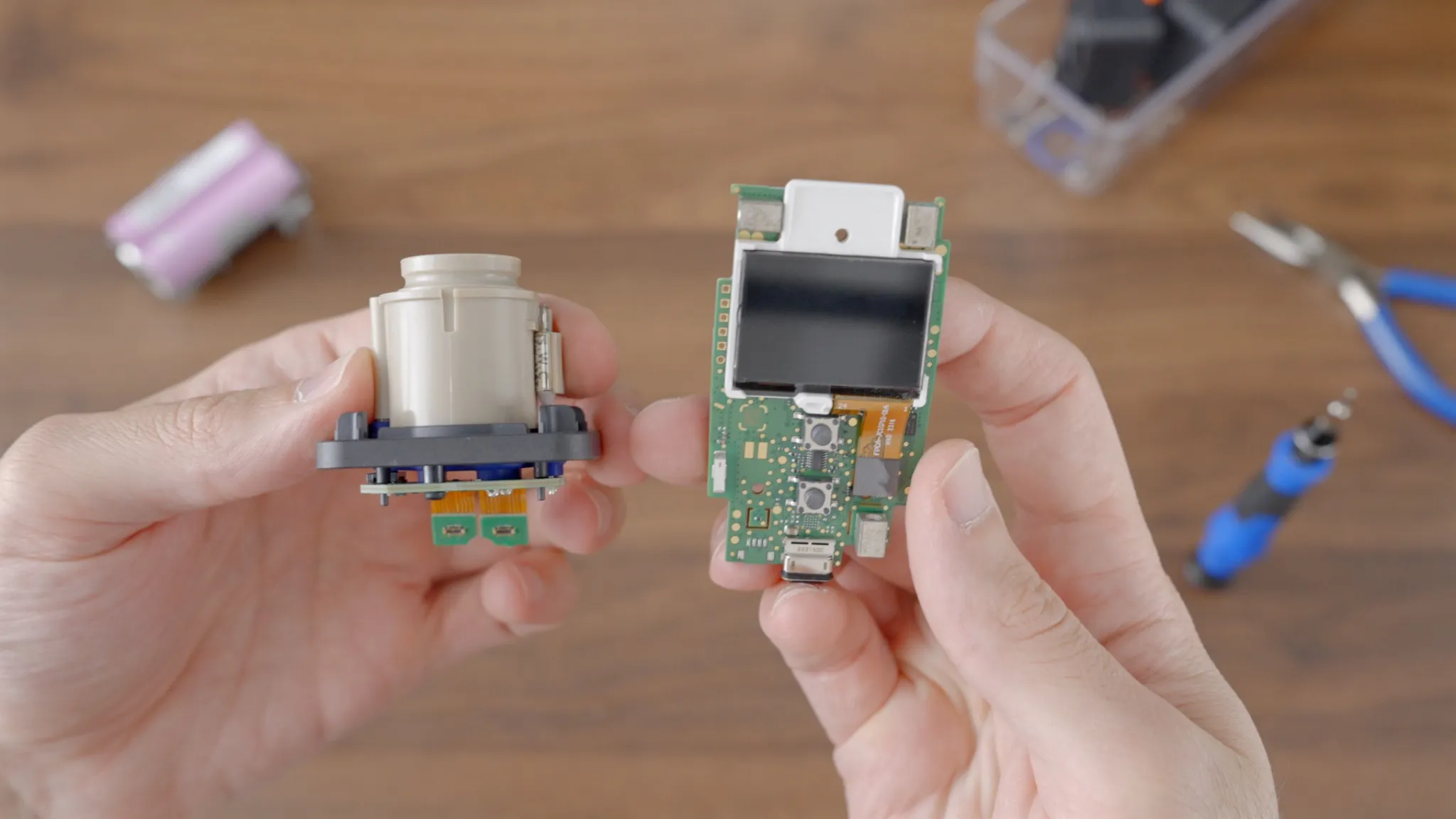

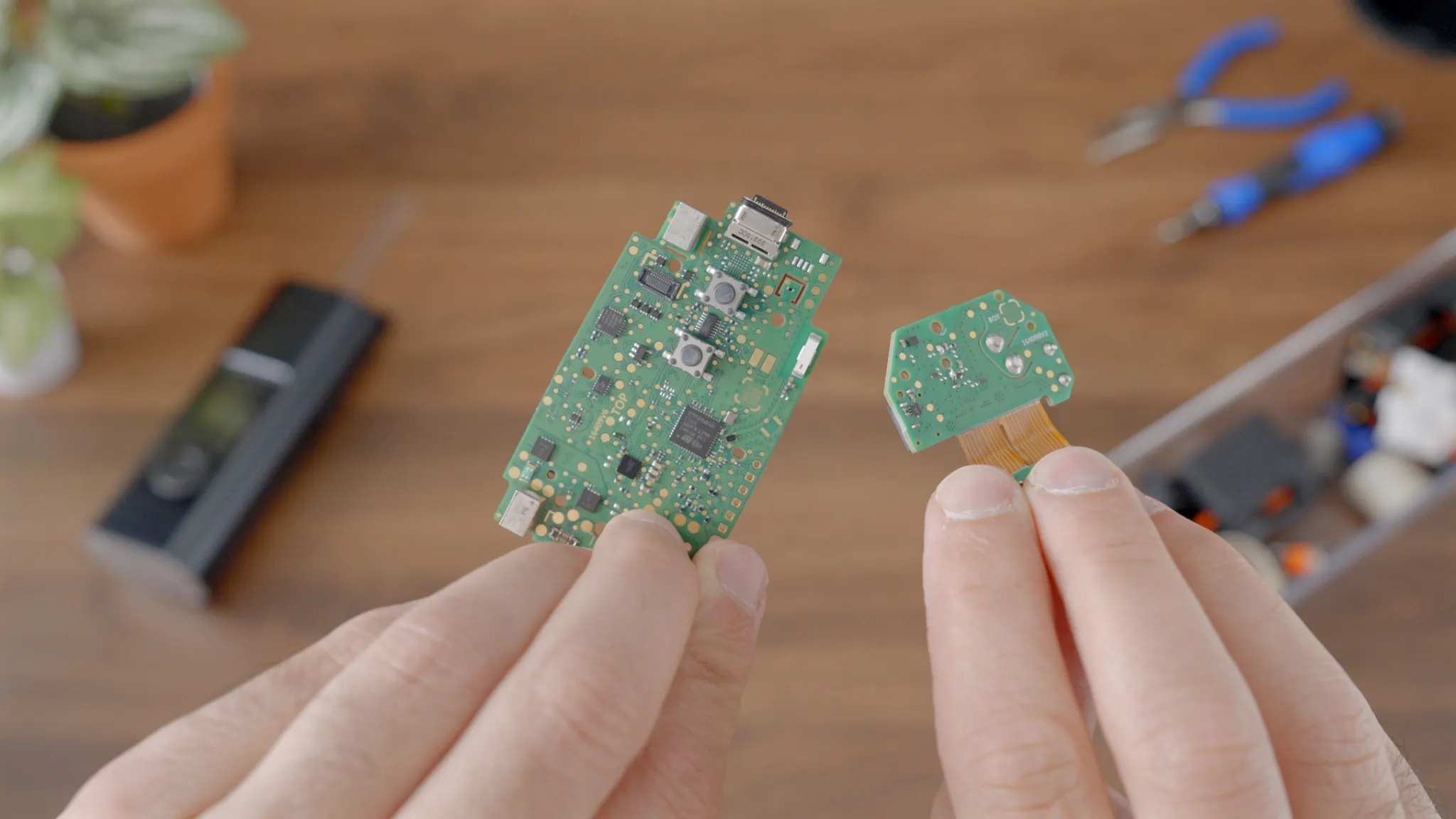

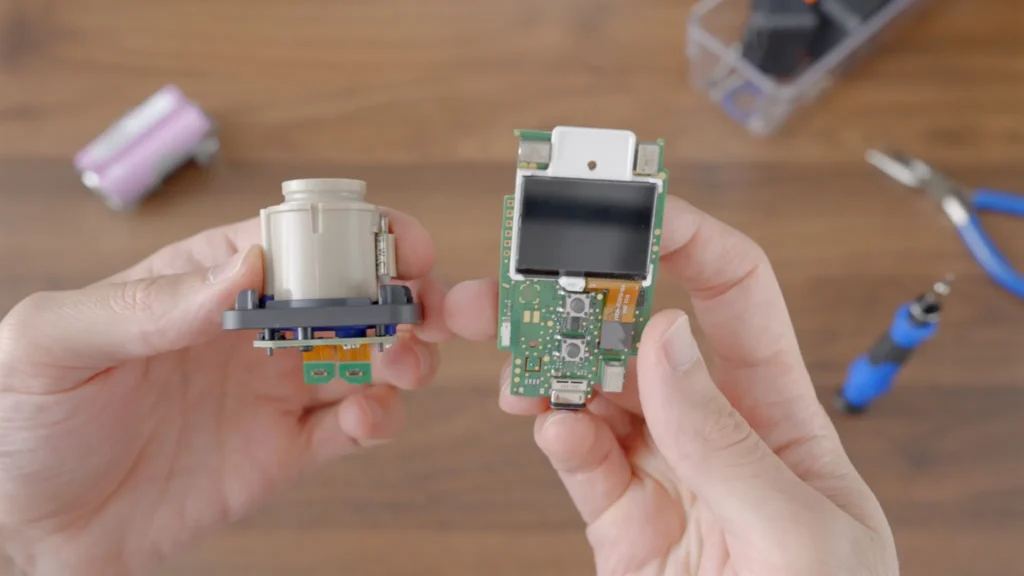

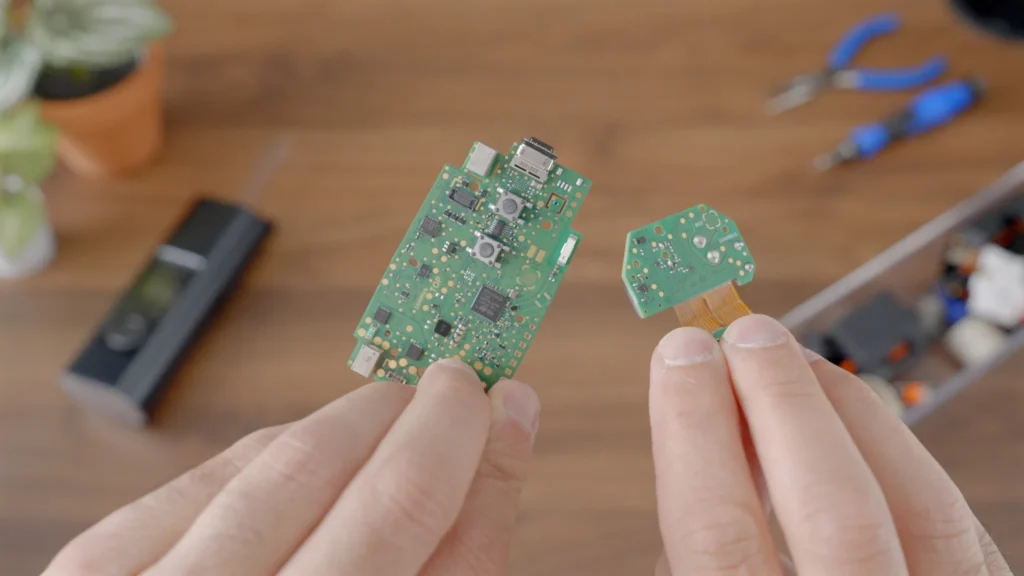

Internal Components: Batteries and Electronics

With the housing removed, we can see the Venty's batteries, screen, buttons, charging port, and power button. The battery pack consists of two Samsung 18650 battery cells, which need to be disposed of properly if drained. The internal layout is clean and efficient, with no loose wires.

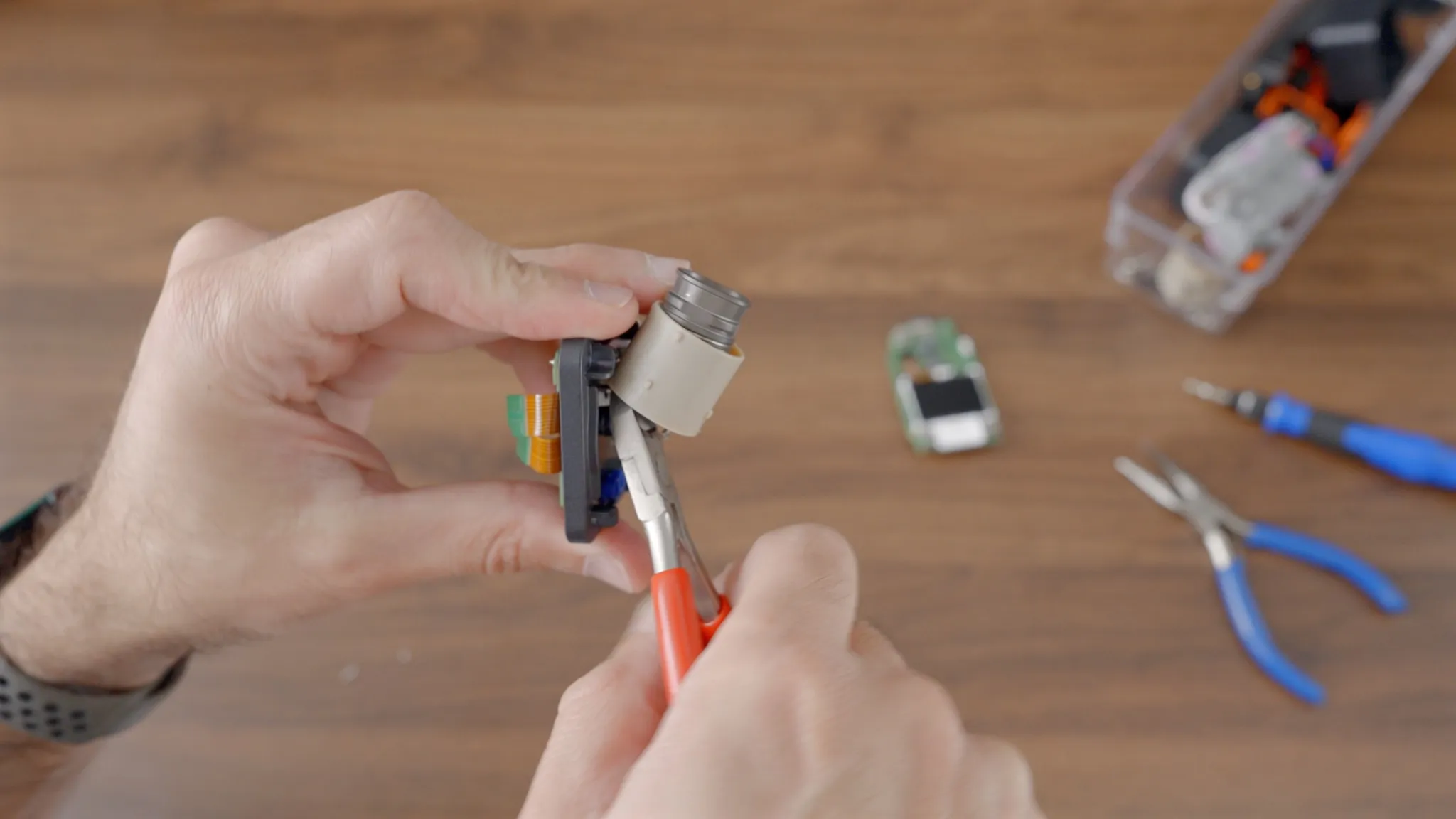

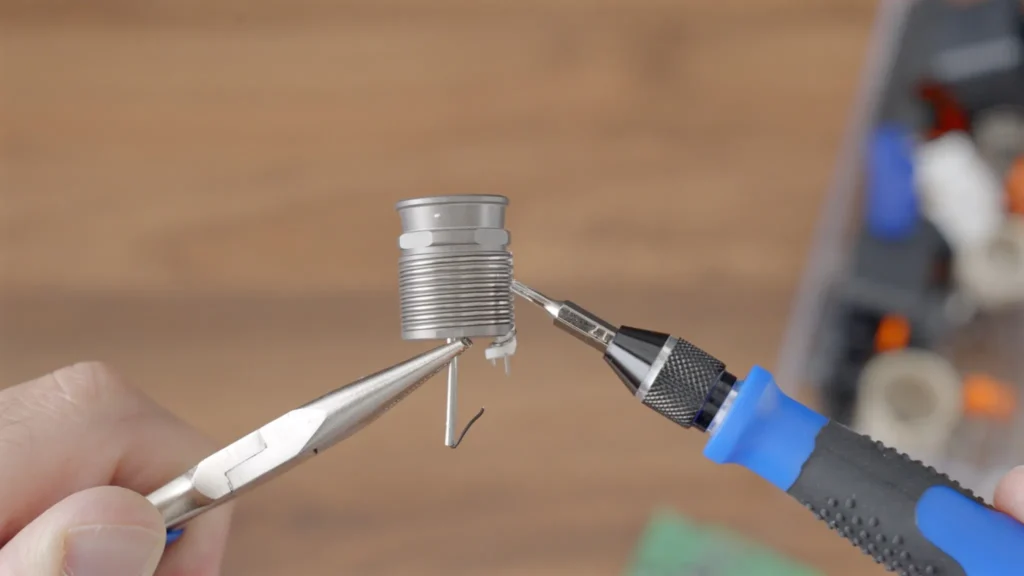

Heating Element and Chamber Assembly

The heart of the Venty lies in its heating element and chamber assembly. The heating element is housed under a cover and connected to the electric board by two thick wires. The chamber, where the herb is packed, is made from an aluminum alloy with a ceramic coating, ensuring durability and ease of use.

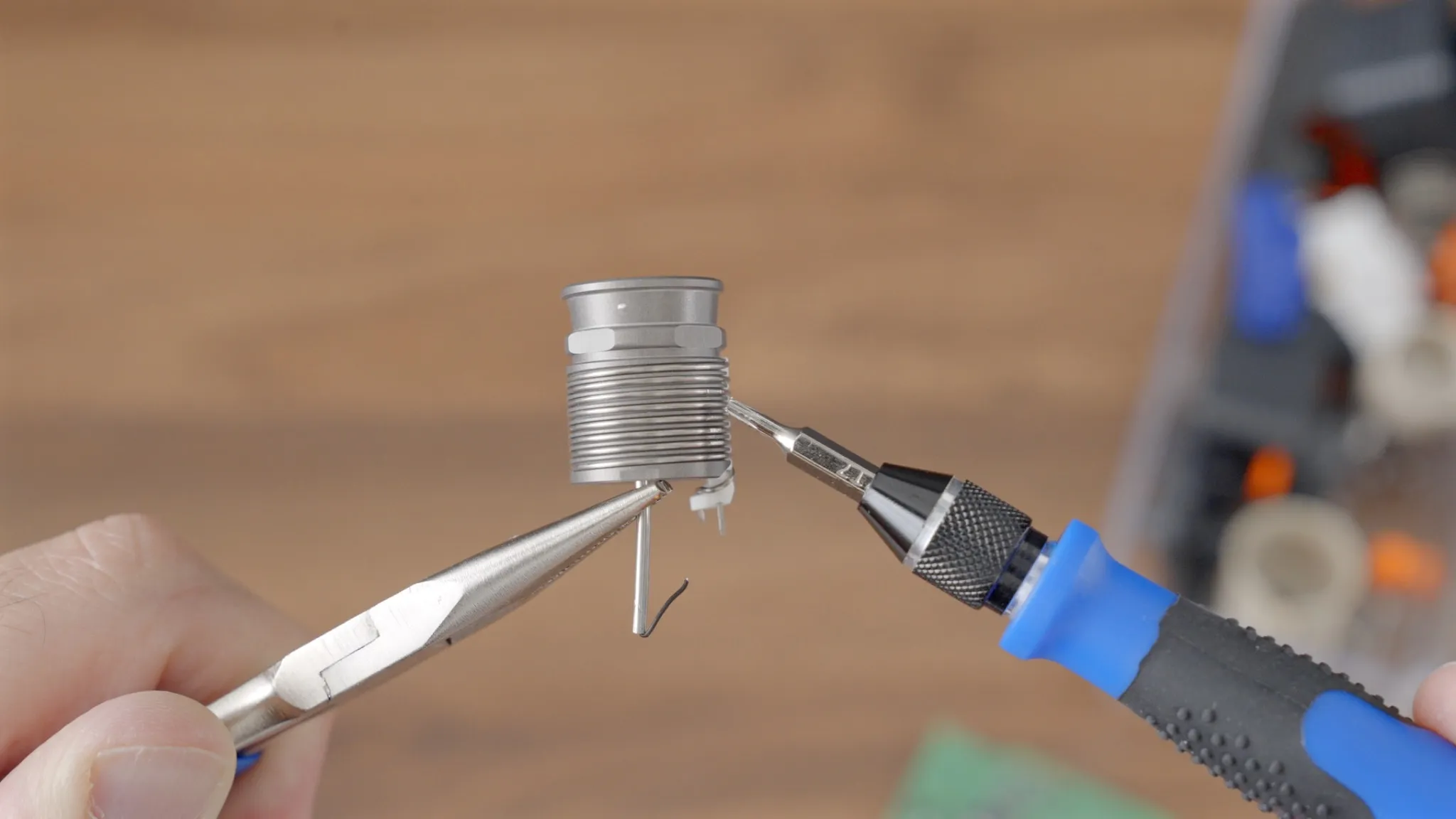

Convection Heating: A Closer Look

The Venty utilizes convection heating, where hot air passes through a hollow cylinder under the chamber, vaporizing the herb. This method enhances flavor and extraction compared to conduction heating. The design integrates all components seamlessly, with the heating wire positioned below the chamber to generate the necessary hot air.

Final Thoughts

After disassembling the Venty, it is clear that the device is a marvel of engineering. Every component fits together perfectly, and the overall build is both clean and straightforward. This teardown has provided valuable insights into the Venty's operation, enhancing our appreciation for its design and performance.

I hope this exploration has been as enlightening for you as it has been for me. Stay tuned for more teardowns, including the upcoming Solo 3.

Thanks for reading, and happy vaping!